Die cut stickers are custom-shaped decals. They are created by cutting the sticker material and the backing paper into any shape desired. Examples are circles, ovals, and unique contoured shapes, such as the outline of a logo. This allows for endless possibilities to make your stickers truly personalized and eye-catching!

How are Die Cut Stickers Made?

Creating die cut stickers involves several steps. First, a custom die is created based on the desired shape or design. The die acts as a template for cutting the stickers. Then, a cutting machine is used to apply pressure and precisely cut the stickers according to the custom die. Depending on the intended use and durability required, various materials can be used for die cut stickers, such as vinyl, polyester, or paper. (we use vinyl for our die cut stickers!) The production process requires precision and attention to detail to ensure the stickers are accurately cut and maintain their shape.

What are the benefits of Die Cut Stickers?

Die cut stickers offer several advantages over their traditional counterparts. Firstly, the ability to create intricate designs and unique shapes sets them apart. Whether it’s a company logo, a personalized character, or an artistic pattern, die cut stickers allow for endless possibilities. Additionally, die cut stickers are durable and resistant to wear and tear, making them suitable for both indoor and outdoor applications. They can withstand exposure to the elements and maintain their vibrant appearance for extended periods.

How are Die Cut Stickers Used?

Die cut stickers have applications in a wide range of industries and contexts. In the business world, they are frequently utilized for branding purposes. These stickers add a professional and memorable touch to products, packaging, or marketing materials. Die cut stickers are also popular in the arts and crafts community, enabling artists and enthusiasts to embellish their creations with unique designs. Moreover, individuals often use die cut stickers to personalize their belongings, such as laptops, water bottles, or vehicles, showcasing their personality and interests.

How to design die cut stickers

To design effective die cut stickers, it’s essential to consider a few factors. Working with vector files is crucial to ensure optimal print quality and scalability. Using software like Adobe Illustrator or other vector-based design tools allows for precise control over the shapes and lines. It’s also important to pay attention to file preparation, including outlining the cut lines and bleed areas, to ensure accurate die cutting. Once the design is ready, there are various options for ordering die cut stickers, ranging from online print shops to local printing services. We think ordering outdoor stickers from Comgraphx is a great choice! Choose a reputable provider that offers high-quality materials and precise die cutting capabilities.

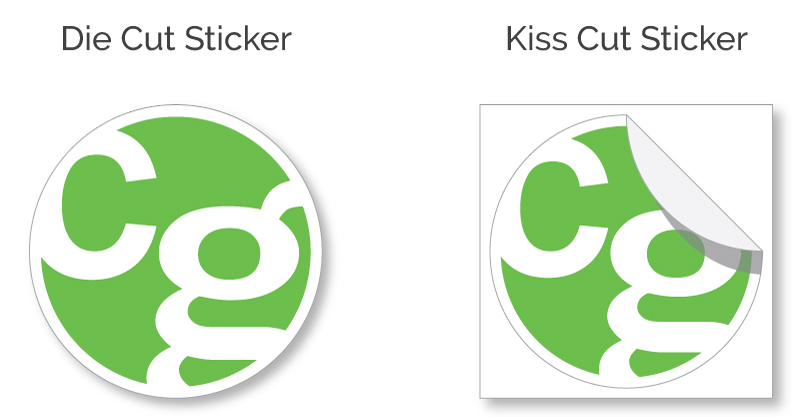

How are die cut stickers different from kiss cut stickers?

Kiss cut stickers are similar to die cut stickers but with a slight difference in the cutting process. While die cut stickers are cut through both the sticker material and backing, kiss cut stickers are only cut through the sticker material, leaving the backing intact. This allows the stickers to be easily peeled off and applied without removing the entire backing. Kiss cut stickers are ideal for designs that require individual sticker removal or for sheets with multiple stickers. They offer versatility in application and provide a neat and convenient user experience.

Conclusion

Die cut stickers open up a world of creative possibilities, allowing you to make a bold statement with visually stunning designs and custom shapes. From branding and marketing to personal expression and artistic endeavors, these unique stickers have found their place in various industries and contexts. By understanding the process of creating die cut stickers and leveraging the right design techniques, you can unlock the full potential of this versatile medium. So go ahead, unleash your creativity, and let die cut stickers leave a lasting impression on your projects.