Stickers have become a popular means of self-expression and branding on various items, from laptops to cars. However, have you ever wondered how long stickers last? Why do some stickers deteriorate quickly, while others endure for years? In this comprehensive guide, we will delve into the crucial factors that influence the lifespan of stickers, equipping you with valuable insights on how to choose long-lasting outdoor stickers.

How Long Do Stickers Last? A Quick Answer

Stickers made from premium materials like vinyl and printed with outdoor inks can last an average of 3-5 years. On the other hand, inexpensive stickers printed with offset, litho, or flexo presses tend to fade within 1-3 months. Stickers made from paper materials have the shortest lifespan, disintegrating within a matter of days.

Factors That Affect Sticker Lifespan: Understanding the Role of Materials, Inks, and Printing Processes

The longevity of stickers is influenced by several key factors, including the materials used, the type of inks employed, and the printing processes applied. Each of these elements plays a vital role in determining how well a sticker withstands the test of time. In this section, we will delve deeper into these factors and explore how they contribute to the lifespan of stickers. So, let’s embark on a journey to uncover the secrets behind durable and long-lasting stickers.

Now let’s explore each of these topics in more detail.

The Impact of Sticker Materials on Longevity

Sticker materials play a pivotal role in determining their durability. Let’s explore some common sticker materials and their expected lifespans.

Paper

Typically used for flyers, business cards, and magazines, paper stickers are not suitable for outdoor use and have a lifespan of zero months when exposed to the elements.

BOPP (Biaxially Oriented Polypropylene, sometimes called Polyprop)

Frequently employed for product labels, BOPP stickers last less than a year outdoors. These stickers are commonly printed on flexographic presses and do not have resistance to fading from the sun.

Vinyl

The most commonly used material for outdoor stickers, vinyl is designed to withstand constant exposure to the elements. It can endure for over five years and sometimes even surpass 7-10 years. Vinyl stickers are highly versatile, capable of conforming to curved surfaces, making them ideal for transportation decals such as boats, trucks, and RV graphics.

Polyester

Another popular outdoor sticker material, polyester offers an extended lifespan exceeding that of vinyl. It is especially suitable for high-temperature environments and heavy-duty equipment like tractors and lawnmowers. Moreover, polyester is environmentally friendly.

The Printing Processes and Inks: Key Determinants of Sticker Longevity

The printing process and the type of ink used significantly impact the outdoor durability of stickers. Here are some insights into these aspects:

The Printing Processes: Screen, Flexo, Digital, Offset

Different printing processes yield varying degrees of longevity. While offset presses are traditionally used for business cards and flyers, flexo equipment is suitable for product labels. However, if you require long-term outdoor durability, screen printing, and industrial digital presses are the recommended options.

Types of Inks and Quality of Pigments

The quality and density of the ink are crucial for sticker longevity. UV inks, such as Comgraphx’s, are known for their strength and resistance to sun-induced fading. In contrast, solvent-based inks may fade over time as the solvent evaporates during drying. UV inks cure when exposed to UV light, ensuring long-lasting durability.

Understanding Sticker Failure

Sticker failure refers to the deterioration or degradation of stickers over time, resulting in a loss of visual appeal and functionality. It can manifest in various ways, such as peeling, fading, cracking, or disintegration. Recognizing signs of sticker failure is crucial to address any material or ink issues that may be affecting their lifespan. In this section, we will explore common causes of sticker failure, including material weaknesses and ink-related factors, and provide insights on how to identify and prevent these issues to ensure long-lasting, high-quality stickers. Let’s dive into the details of sticker failure and learn how to keep your stickers looking vibrant and intact.

Material Failure

Inferior sticker materials may deteriorate due to moisture absorption, leading to flaking and disintegration when exposed to the elements.

Ink Failure

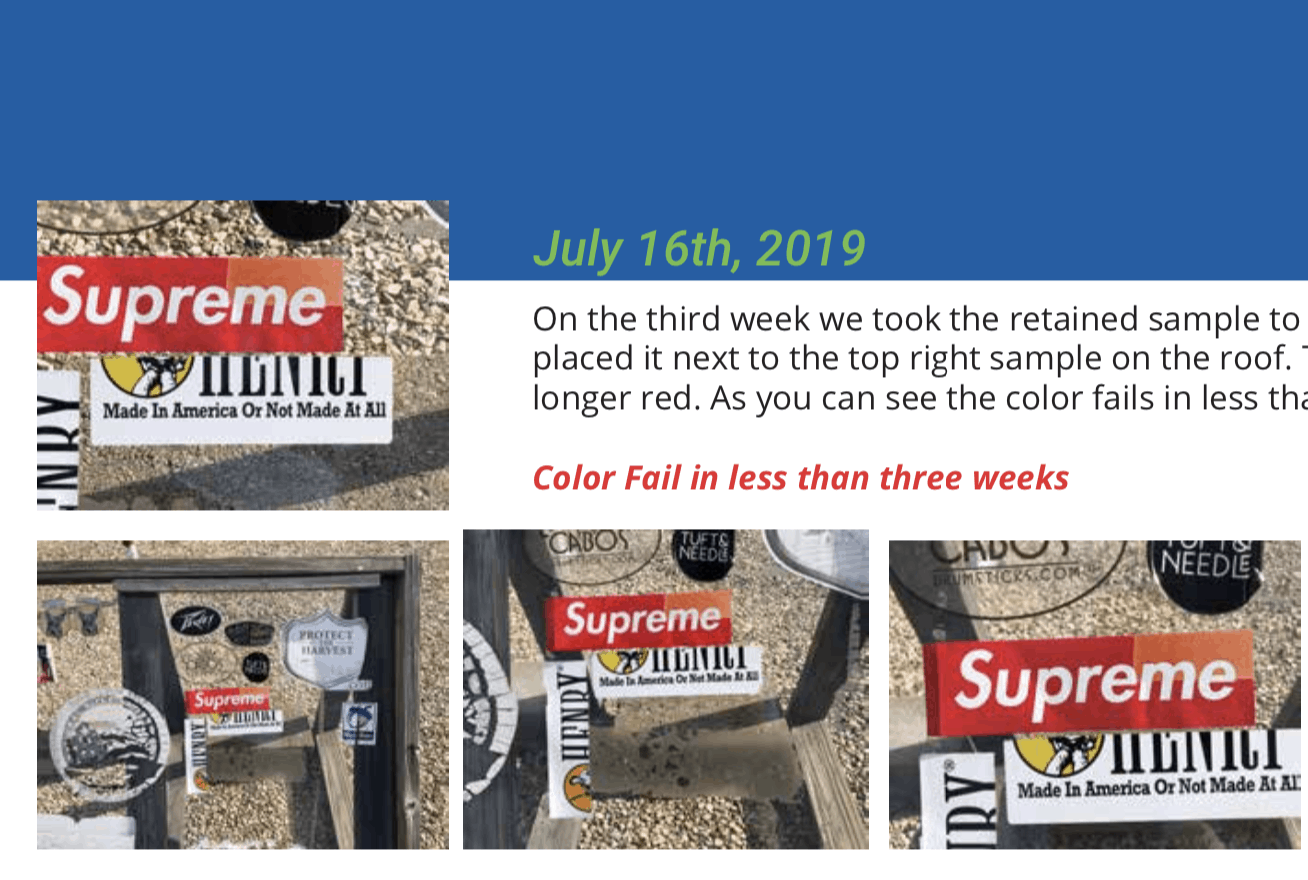

Insufficient pigment in the ink can cause stickers to fade prematurely, compromising their longevity.

The Role of Laminates in Sticker Longevity

Laminates can enhance the longevity of stickers by providing an additional protective layer. They shield the sticker from the elements, including UV rays, moisture, and abrasion. Choosing high-quality laminates can significantly extend the lifespan of your stickers.

Laminates are not necessary though if the stickers are screen printed with UV inks. The vinyl base material and inks are durable enough to withstand outdoor elements even without laminates.

Consider all of these factors when buying outdoor stickers

By considering the sticker material, printing process, type of ink, and the potential impact of laminates, you can make informed decisions when selecting stickers that will last. Remember, materials and printing processes are crucial factors in determining sticker durability. For high-quality, long-lasting stickers, consider the versatility of vinyl and the extended lifespan of polyester. Additionally, selecting the appropriate printing process and ink type, such as UV inks, can ensure vibrant colors and resistance to fading. With these insights, you are well-equipped to choose durable stickers that will stand the test of time.

Check out our custom outdoor stickers

Discover how our printing processes and high-quality materials can provide the durability and longevity you seek for your stickers