Selecting the ideal sticker material can feel overwhelming—like wandering through a maze of options with no clear path. Shouldn’t your printer handle the technical details? While it’s tempting to leave everything in your printer’s hands, not all printers specialize in stickers. Many focus on general printing and may recommend materials or processes not optimized for outdoor durability.

At Comgraphx, we’ve seen this happen far too often. Customers come to us after their “durable” stickers fade, peel, or fall short because they rely on printers without the expertise to choose the right combination of materials, inks, and processes. That’s why understanding the basics yourself is so important—it empowers you to ask the right questions and avoid costly mistakes.

In this guide, we’ll break down the top outdoor sticker materials, their strengths, and when to use them, so you can confidently create stickers that look great and stand the test of time.

Sticker Materials vs. Label Materials: What’s the Difference?

First, let’s clarify a common question: Are stickers and labels the same thing? Technically, both involve sticky materials, but they serve different purposes. Stickers are often used for branding, promotion, or decoration, while labels are typically functional, and designed for packaging or product identification.

For more details, check out our in-depth blog on stickers vs. labels.

This post, however, will focus specifically on materials suitable for outdoor stickers, which require durability and weather resistance.

Top 7 Materials for Outdoor Stickers

Here’s a breakdown of the most popular outdoor sticker materials, each with its unique strengths:

1. Vinyl Stickers: The Industry Standard

Vinyl is the MVP of outdoor stickers. Its versatility, durability, and affordability make it the go-to material for everything from brand promotions to giveaways. Vinyl stickers are flexible, weatherproof, and available in both white and clear finishes. The most popular style of outdoor vinyl sticker is the classic die cut sticker.

- Thickness: Typically 4 mils, with a soft, pliable texture. Check out our blog to learn more about sticker material thickness.

- Key Features: Conforms to curved surfaces, resists bubbles, and is available in matte or gloss finishes.

- Best For: Marketing giveaways, bumper stickers, and general outdoor use.

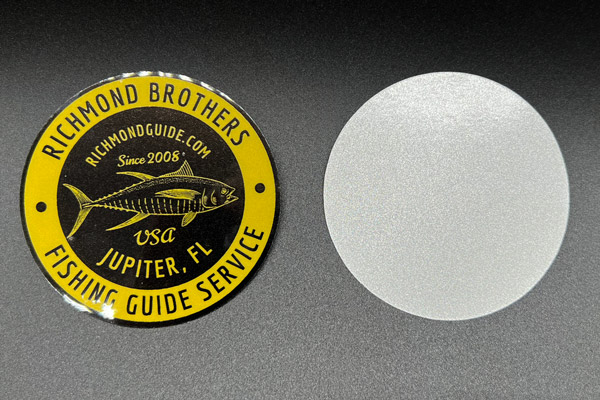

2. Polyester Stickers: For Heavy-Duty Applications

When durability is non-negotiable, polyester stickers are the answer. These are ideal for industrial applications like equipment decals or under-the-hood labels. Polyester resists high temperatures, abrasion, and UV exposure.

- Thickness: 2 mils (thinner, but tougher than vinyl).

- Key Features: Comes in finishes like brushed chrome, bright silver, or pearlescent white.

- Best For: Machinery labels, water heater decals, or premium-looking brand stickers.

3. Static Cling Stickers: Residue-Free Options

Static cling material sticks to glass and other smooth surfaces without adhesive. These are perfect for temporary or repositionable decals.

- Best For: Retail window promotions, seasonal graphics, or parking permits.

4. Heavy-Duty Stickers: Extra-Thick and Tough

For extreme conditions, heavy-duty stickers are the answer. These ultra-thick materials are designed to withstand abrasions, impacts, and heavy outdoor use.

- Best For: Helmets, motorcycles, or construction equipment.

5. Holographic Stickers: Playful and Durable

Holographic stickers aren’t just for fun—they’re surprisingly resilient. With their eye-catching iridescent finish, they add a playful yet professional touch to any design.

- Best For: Event giveaways, limited-edition designs, or retail promotions.

6. Reflective Stickers: Safety Meets Style

Reflective materials are commonly used for safety applications, but they also work well for branding. These stickers shine when exposed to light, making them highly visible.

- Best For: Road signs, safety labels, or eye-catching car decals.

7. Shiny Chrome Stickers: A Polished Look

Shiny chrome stickers offer a mirror-like finish that stands out. When combined with white ink, they create a bold, unique look.

- Best For: Premium brand stickers, promotional items, or specialty decals.

What Material is Best for Bulk Stickers?

When it comes to bulk stickers, vinyl is the material of choice, and screen printing is the process that ensures maximum outdoor durability. Screen printing delivers vibrant, long-lasting colors that hold up against the elements, making it ideal for large quantities of outdoor stickers.

One of the biggest advantages of screen printing in bulk is its cost-effectiveness. Unlike digital printing or online sticker printers that excel in small runs, screen printing shines in high-volume production. This process not only lowers your per-sticker cost but also provides a level of durability that’s hard to beat.

Want to learn more? Explore our wholesale and bulk sticker printing options through our CGpro program and see how we can deliver the perfect combination of quality and value.

Bonus: Laminates Enhance Both Protection and Style

Laminates aren’t just about durability—they can also transform the look of your stickers. For eco-solvent or offset prints, laminates protect against UV rays, scratches, and moisture. For screen-printed or high-quality digital stickers, laminates are more about aesthetics, offering options like glossy or matte finishes to elevate your design.

- Glossy Laminate: Adds depth and vibrancy to colors.

- Matte Laminate: Creates a sophisticated, muted look.

What About the Adhesive?

Choosing the right material is only part of creating a durable outdoor sticker—don’t forget the adhesive! The adhesive is what keeps your sticker securely in place through rain, wind, and extreme temperatures.

Different applications call for different adhesives. For instance, a car bumper sticker needs a semi-permanent adhesive, while an outdoor equipment sticker needs a more aggressive and permanent solution. The right adhesive ensures your sticker performs well, no matter the surface or conditions.

Learn more about the adhesives we use and why they matter in our blog post: What Adhesives Do We Use on Our Stickers?

Other Specialty Materials for Outdoor Stickers

Want something unique? Specialty materials like metallic finishes, textured patterns, or glitter effects are great for limited-use decals or event promotions. These options help your stickers stand out while showcasing your creativity.

Our Recommendation: Samples Speak Louder Than Words

Still unsure which material is right for your project? Order our Pre-Printed Sample Pack to explore all of our material options firsthand. If you want to see your own artwork in action, try our Custom Sample Pack instead. Experiencing the look and feel of the materials will give you the confidence to choose the perfect option for your stickers.

Ready to Start Your Outdoor Sticker Project?

With so many materials to choose from, your stickers are sure to stand out in both design and durability. Start your project today and create outdoor stickers that leave a lasting impression.