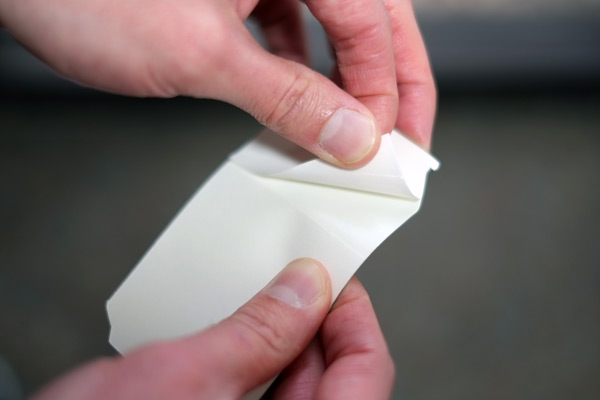

Using a back slit on your die cut stickers can offer several benefits. Stickers are a popular way to promote your brand or add personalization to your belongings. However, separating the sticker from the backing paper can be frustrating. This is where a back slit comes in handy. Adding a simple cut to the backing paper makes the sticker application process much easier and more efficient.

What is a back slit on a sticker?

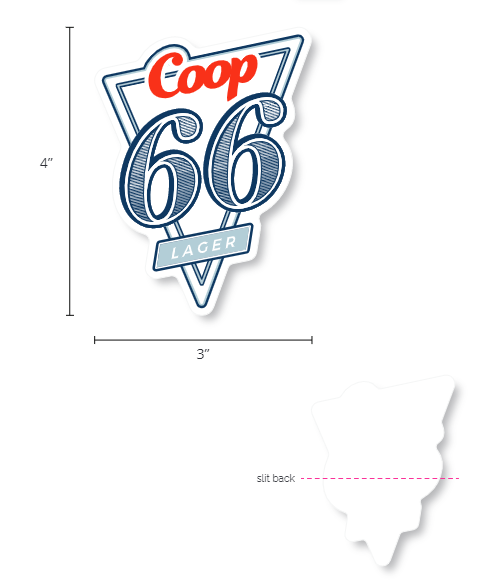

A back slit is a small cut added to the backing paper of a sticker during the manufacturing process. It serves as a starting point for peeling off the sticker from the backing, which is especially useful for dealing with small or intricate stickers. Importantly, the back slit doesn’t affect the appearance of the final product once it’s applied to a surface.

Why You Should Care About Back Slit Stickers

Purchasing stickers with back slits isn’t just a matter of convenience; it’s a sign of a high-quality product. Customers appreciate stickers that are easy to use, and the presence of a back slit ensures just that. Without a back slit, users might find themselves struggling to remove the backing paper, potentially damaging the edges or even rendering the sticker unusable.

Common Names for Back Slit Stickers

Back slit stickers go by various names depending on the sticker printer, such as crack and peel stickers, easy-peel stickers, split-back stickers, or simply back slitting.

Types of Stickers That Normally Come with a Back Slit

Back Slit Stickers – A Long-standing Tradition

Back slit stickers have been around for decades, and they’re a well-established method for creating high-quality decals. Sticker manufacturers have used this finishing technique for years, and specialized machines are designed specifically for slitting the back of decal liners.

The Rise of Non-Back Slit Stickers

With the advent of online digital sticker printers in recent years, non-back slit stickers have become more common. However, these stickers can lead to confusion among consumers, as they may resemble thick paper rather than proper stickers. To ensure top-notch results, it’s crucial to find a printing partner capable of providing back slit stickers.

Making Back Slit Stickers: Cutting and Depth Considerations

Creating back slit stickers involves several methods, including using steel rule dies or blades on machinery to slit the liner. Achieving the proper depth of the cut is crucial to ensure that only the backing paper is cut and not the adhesive or label material, which can be challenging due to the thin materials used.

Customizing Back Slit Locations

For certain sticker styles, specifying the location of the back slit is essential. For instance, for long and narrow stickers like classic bumper stickers, a vertical slit placed towards the left or right side facilitates easy application for end-users.

Back slit stickers greatly improve the user experience

In conclusion, incorporating back slits into your stickers can greatly improve the sticker application experience for your customers. It ensures a hassle-free process and indicates a commitment to providing top-quality products. So, next time you’re getting stickers printed, make sure to opt for back slits and enjoy the benefits they offer!